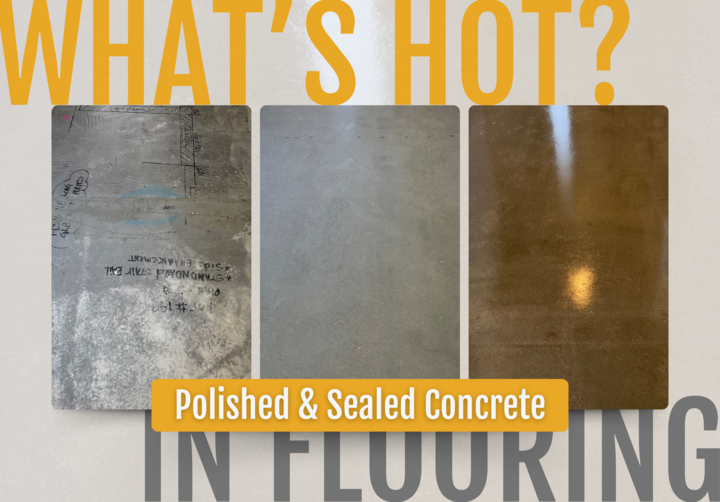

What’s hot in concrete flooring? Polished and sealed concrete!

What’s is polished and sealed concrete?

Less is more and easy maintenance is the thing now a days. Whether it’s commercial or residential owners are finding that polished and sealed concrete is the way to go. It let the business or the home speak for itself and have little to no maintenance flooring. Having a weathered and distressed, nearly indestructible floor now that’s a huge incentive. owners all over the city are tearing up their flooring and using the concrete underneath as a finished product. let’s face it people are starting to understand that Carpet gets dirty and damaged way to quickly. All this tile that’s been laid for all these years the grout gets dirty and is unable to be restored. With more and more people, focusing on hyper allergenic environments to include their flooring which let’s face it is usually the thing that gets the dirtiest the fastest this is the answer and in high demand! Another added benefit to this whether it is commercial or residential is that when it comes time to sell the property the next owner can literally just put their new flooring right over concrete polish without any kind of delay on removing old flooring if the polishing isn’t desired. on top of that, it is a flooring that would never have to be replaced even if it was neglected, it could be brought back to life.

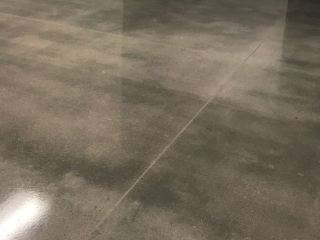

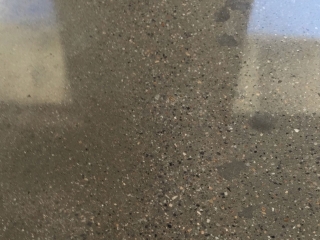

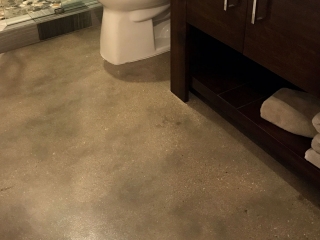

Take a look at our gallery below to see what advantages polished concrete provides to traditional concrete. (for pricing & information click here)

A Few Of Our Videos

The Advantages of a Polished Concrete Floor

The biggest advantage is if you scratch the floor or it is damaged in some way, it can be repaired much easier than other concrete coatings. Most concrete polishing is done directly to the slab, which is a huge advantage for longevity, as it won’t peel or chip, due to wear and tear. Polished concrete is very beneficial for both allergy and sanitation purposes. We have a lot of requests for this reason alone.

When customers are looking for something that will stand the test of time. Concrete polishing is that answer! Ultimately, it is the foundation of the home or business! Further, polished concrete is very neutral and calming and it’s appealing to look at. A polished concrete floor is of great advantage when selling a property as it adds tremendous value to the look and it keeps the curb appeal high. Finally, concrete polishing is very easy to cover with other floorings if a client wishes or a buyer desires.

The polishing process varies depending on whether the concrete is new or has had some type of flooring on it previously. Regardless, the polishing process will require several steps. Let’s take a look at what the processes are and the effects the previous flooring may have to the end result of your polished concrete.

Previous Flooring: Tile

The most difficult polished concrete floors are the ones which started with tile on them. In my judgment, the most important thing to understand is chances likely; the tile marks will show back through the polish. The reason being there is acid in the tile grout and in the mortar that holds down the tile. The tile could be a month old or 10 years old and you still could have the same outcome, which is a ghosting of where the tile was. Some of my clients find this look unique and interesting and just love it. Others do not. I always discuss this outcome initially with a client. I am very patient with the tile removal process and am very careful when I remove the tile, so as to not ding or scrape the concrete underneath the tile, as it will show through in the final process. This will often happen to some degree. However, minimalizing it is the goal.

Previous Flooring: Carpet

Other types of flooring on concrete, can easily be removed, carpet being one of them. If carpet had been present previously, all of the glue, magic marker and paint that has been hidden by the old flooring will all be ground down and then polished off. The tack strip that holds the carpet down is another issue. There will be a dime to quarter size holes every 6 inches up against the wall. We fill in each hole and any divots we may find in the middle of the floor. However, it’s difficult to match the concrete fill to match exactly like the rest of the concrete so that it will remain visible to some degree. We take an additional step when we begin to grind the concrete. We save some of the powder from the grind to mix into the patch material. This is the best chance to get the closest match possible. If there’s some type of flooring to be removed, there will be some residual flaws. However, the end result will be a beautiful and incredibly durable floor. It is the foundation of the building and something most people enjoy when done right.

Preparation & Polishing

To minimalize any scratches and blemishes we grind the concrete first. Now the polishing process begins. The customers desired result will determine how many passes it will take to polish the concrete. The more passed we take the crisper a reflected image will be, meaning each pass will give the concrete a deeper shine. A number of passes does determine the time and the cost involved.

Sealer & Wax

It is Floor Seasons personal belief polished concrete shouldn’t be left without a sealer and wax on it. Less experienced contractors may give you different advice. The fact is sealer and wax support the floors longevity. The sealer and wax protect the concrete polishing from drops and spills making it an easy cleanup. Let’s say, for example, if soda or some other chemical were spilled on the unprotected polished floor, it’s very possible it’s going to eat the polished finish off thus needing to be re-polished. If a sealer and wax were applied after the polishing process had been completed, these areas would still look beautiful, more often than not.

Flooring Maintenance

Sealing and waxing protect the polishing and thus the investment. If something spills, it can be wiped up. The wax would need to be scrubbed every now and again and then reapplied a very inexpensive process. We teach the waxing process to our customers so they may do their own maintenance. An added value the use of sealer and wax create is the concrete will not have to be polished as much due to the sealer and the wax being high-gloss; Thus, making it more affordable and more protected!

Adding Color

Most polished concrete will be several different colors of gray. If the floor gets scratched, this makes it relatively easy to fix because there’s no color other than the natural grays. Some of my customers do request color, and this can be done during the polish stage. There is a myriad of colors to choose from for that perfect look customers desire.

Pricing

Pricing for polishing varies. Previous flooring removal and size are the two main factors in pricing. Other factors to consider, would be what kind of sealer and wax is chosen and how high of a sheen is desired. Brand new concrete from start to finish, based on 1500 ft.² space, can average between $5 and $9 a square foot. Concrete that has to have old flooring removed before the start of the project can average between $7 and $12 a square foot.

Polished Concrete Advantages

Polishing concrete offers many advantages when compared to other traditional floor coverings. The following can be considered the most important advantages:

- Polished concrete protects the concrete from damage from small drops and scratches.

- It offers a hard wearing durable surface able to withstand heavy and continuous traffic.

- Durable and easy to clean.

- Resists oil stains, beads water, and wipes super clean.

- It won’t peel or chip, due to wear and tear.

- Polished concrete is very beneficial for both allergy and sanitation purposes.

- Prevent wear and tear to the existing concrete floor.

- Environmental friendly alternative solution to other floor coverings.

- Require little or no major maintenance.